Compact

Cotton Yarn

Globally Recognised

Quality

We use globally advanced techniques to manufacture the best quality yarn and maintain international standards. From Blow Room to Winding, we are equipped with the most modern technologies. Our textile machines are sourced from the best global brands like RIETER (Switzerland), ELECTRO-JET (Spain), SCHLAFHORST (Germany) and LMW (India). A World-Class Lab ensures proper quality control. To ensure consistency in Compact Cotton Yarn evenness, hairiness and strength, we utilise LOEPFE (Switzerland) equipment that consistently tests and monitors the product. Every single cone of yarn is passed through ultraviolet room that helps us detect any shade variations.

Revolutionary

Compact Yarn

Spinning

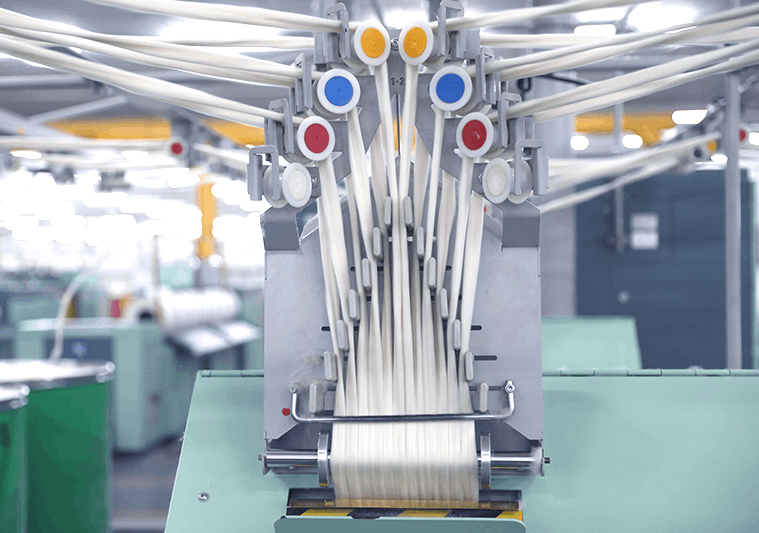

Compact Yarn Spinning is the new global standard. In the process, fibre strands are drawn by the drafting system and condensed before being twisted. The result is a remarkably improved yarn, both in quality and efficiency.

Higher lustre yarn

Smoother yarn fibres

40-50% Better abrasion fastness

20-30% Lower hairiness (Ster Apparatus)

60% Lower hairiness (Zweigle Apparatus)

8-15% Higher tenacity & elongation at break

Smaller mass irregularity

8% Production increase

High Yarn

Count Range

SVP Group makes 100% Cotton Combed & Carded Yarn that is suited for use in high-quality end products. The high count range ensures that yarns are fit for the global stage.

| PRODUCTS | COUNT RANGE |

|---|---|

| Single String Yarn | Ne 24/1 to Ne 140/1 |

| Double Ring Yarn | Ne 24/2 to Ne 140/2 |

| Single Open End Yarn | Ne 6/1 to Ne 24/1 |

| Double Open End Yarn | Ne 6/2 to Ne 24/2 |

A Multinational

Manufacturer

Facilitated

By Technology

We ensure the best quality of our yarns and use globally advanced techniques to maintain international standards. From Blow Room to Winding, we are equipped with the most modern technologies . Our textile machines are sourced from the best global brands like RIETER (Switzerland), ELECTRO-JET (Spain), LMW (India) and SCHLAFHORST (Germany). A World-Class Quality Control Lab ensures proper quality control. They use test machines by USTER (Switzerland) and ensure no deviation from the highest standards. To ensure consistency in Compact Cotton Yarn evenness, hairiness and strength, we utilise LOEPFE (Switzerland) equipment that consistently tests and monitors the product. We also pass every single cone of yarn through our ultraviolet room that helps us detect any shade variations.

Certifications

The Proof Of Our Consistency

Some of our globally recognised certifications and credentials which validate our consistent quality commitment.

GOTS (Global Organic Textile Standards)

OEKO-TEX STD-100

Fair Trade

B.C.I (Better Cotton Initiative)

Inditex

U.S Cotton Trust Protocol (Membership)

Integrated Management System (Ist Stage Audit Completed) In Process

ISO-9001: 2015 (QMS)

ISO-14001: 2015 (EMS)

ISO-45001: 2018(OH&S)

Inditex

U.S Cotton Trust Protocol (Membership)

Integrated Management System (Ist Stage Audit Completed) In Process

ISO-9001: 2015 (QMS)

ISO-14001: 2015 (EMS)

ISO-45001: 2018(OH&S)

Inditex

U.S Cotton Trust Protocol (Membership)

Integrated Management System (Ist Stage Audit Completed) In Process

ISO-9001: 2015 (QMS)

ISO-14001: 2015 (EMS)

ISO-45001: 2018(OH&S)

Inditex

U.S Cotton Trust Protocol (Membership)

Integrated Management System (Ist Stage Audit Completed) In Process

ISO-9001: 2015 (QMS)

ISO-14001: 2015 (EMS)

ISO-45001: 2018(OH&S)

Sohar, Oman

Logistical Efficiency Through Port Proximity & State-Of-Art Technology

A Blend Of efficiency, connectivity & growth

SVP Global has established a new plant at Sohar Free Zone (SFZ). A highly automated unit, it is spread over 27 hectares. It manufactures the best Compact Cotton Yarn used in European markets. The location provides strategic advantage like reduced power cost, low cost of capital, connectivity and tax benefits. SV Pittie Sohar Textiles (FZC) is the first major cotton spinning unit in the GCC region. It operates at 95%+ capacity utilization and further expansions are under progress.

The plant manufactures a wide range of cotton yarn products which are exported to China, Bangladesh, Pakistan, Turkey, Egypt, Germany, Vietnam, Portugal among others.

We employ more than 1,700 people. It has contributed to the social and economic development of the region. In April 2019, an onsite training centre was established for the citizens of Oman. It especially focused on training young women for skilled jobs at the unit.

We are on the course to double our capacity in the F.Y. 2021-22.

For more information about our Oman operations, please visit www.svpoman.com

Strategic

Opportunities & Advantages

Raw material procurement and sales offtake (for next 2-3 years) in place

Logistic and operational efficiencies

Low power cost

Free Trade Agreements of Oman with the U.S.A

Tax-free zone

Low-cost borrowings

Trained and employed more than 1000 Omanis

Access to markets that are not accessible from India due to trade barriers and political relations i.e. Turkey, Pakistan, etc.

Tamil Nadu,

India

The State Where Our Growth Began

A combination of location proximity and cost efficiency

The first of manufacturing units location of SVP Global is involved in the manufacturing of Cotton Yarn, Compact Yarn, Citra Yarn, Blended Yarn and Open End Yarn. It is operational at 95%+ capacity utilisation. The facility ensures logistical cost efficiency as they are in proximity to raw material and textile hubs. The aggregate capacity is 98,000 spindles. It manufactures yarns in the range of Ne 20s to Ne 60s. We believe in environmental safety and have installed green energy sources in our plants to reduce our operational cost.

Rajasthan,

India

Further Expansion Opportunities That Led To Ou

An amalgamation of strategic & logistic opportunities

Our most modern manufacturing unit in Jhalawar, Rajasthan was set up in June 2017 in a record time of 9 months. With state-of-art technology, the facility has a manufacturing capacity of 1,50,000 ring spinning spindles for Compact Cotton Yarn and 2,400 rotors for Open End Yarn. The ring spinning spindles have a production capacity of 52 metric tonnes/ day and produce yarns in the count range of Ne 30s to Ne 120s. The open end rotors have an aggregate capacity of 18 metric tonnes/day and produce yarns in the count range of Ne 10s to Ne 30s.

The plant operates at 95%+ capacity utilisation and is powered by green energy that helps us reduce our operational costs.

Strategic

Advantages Of Rajasthan

Over the years, Rajasthan has established itself as an investment destination. With widely available natural resources, investment-friendly policies, an unexplored talent pool and a secular environment, it provides the best technical, human and financial opportunities. The Plant is located close to cotton belt and easy access to the port.

SVP Global

Advantages

TUF interest subsidy- 2% (available for 1,00,000 spindles units)

State interest subsidy- 6% + 3%

Power benefits- 100% electricity rebate